Safeguarding Groundwater

Realtime Environmental Monitoring and Groundwater Protection

Sensoil provides real time data and analytics from the vadose zone for smart decisions

In this era of climate change, groundwater, environmental sustainability and responsible water resource management are paramount.

Sensoil’s innovative Vadose-zone Monitoring System™ (VMS) providing easily accessible, continuous data and analyses from land surface to groundwater, throughout the unsaturated zone. Sensoil’s solution generates and provides operational data and analyses for the management and protection of the earth’s most important natural water resource – groundwater.

Vadose zone Monitoring for Proactive Decisions

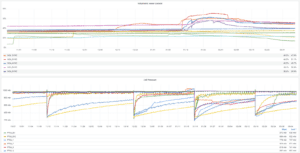

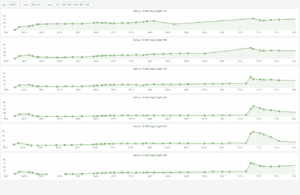

Equipped with sampling units and advanced real-time data collection instrumentation, VMS provides critical hydrological and chemical information, on water percolation velocities and contamination migration fluxes in the unsaturated zone.

VMS allows for proactive, time sensitive decision making in diverse applications including: Groundwater management, protection and research; Agritech; Earthen dam, levee and reservoir Safety; Contaminated land and PFAS Remediation and Smart mining.

Groundwater Protection & Management

Sensoil’s Vadose-zone Monitoring System (VMS) provides real time information on pollution processes

Earthen

Dam Safety

Sensoil’s Vadose-zone Monitoring System (VMS) provides continuous information on dam sediment moisture and real-time seepage.

Contaminated Land Remediation Optimization

Sensoil’s Vadose-zone Monitoring System (VMS) enables optimization of in-situ bio-remediation.

Agricultural Soil Monitoring

Sensoil’s Agricultural Soil Monitoring solution enables continuous, real-time monitoring and sampling of soil nutrients and moisture

Responsible Mining Management

Sensoil’s Vadose-zone Monitoring System (VMS) provides real-time data on water flow velocities and chemical evolution

Groundwater Protection & Management

Sensoil’s Vadose-zone Monitoring System (VMS) provides real time information on pollution processes

Earthen Dam Safety

Sensoil’s Vadose-zone Monitoring System (VMS) provides continuous information on dam sediment moisture and real-time seepage.

Land Remediation Optimization

Sensoil’s Vadose-zone Monitoring System (VMS) enables optimization of in-situ bio-remediation.

Agricultural Soil Monitoring

Sensoil’s Agricultural Soil Monitoring solution enables continuous, real-time monitoring and sampling of soil nutrients and moisture

Responsible Mining Management

Sensoil’s Vadose-zone Monitoring System (VMS) provides real-time data on water flow velocities and chemical evolution

Harnessing the Power of VMS

Sensoil’s Vadose-zone Monitoring System (VMS) provides continuous, realtime data and on-demand sampling from the unsaturated zone. VMS data is easily accessible through the VMS cloud-based application. VMS data and analyses equip stakeholders with powerful decision-making tools.

Sensoil enables early detection, proactive time sensitive decision making, and implementation of effective mitigation strategies.

VMS empowers research institutions, industries and regulatory bodies to actively contribute to groundwater management and protection.

Vadose Zone Samples, Data and Analysis

The World Bank Water Report (2023) states that “Groundwater underpins the development of agriculture, cities, and critical ecosystems”.

Sensoil’s proven Vadose-zone Monitoring System™ provides critical hydrological and chemical information on water percolation velocities and contamination migration fluxes in the unsaturated zone. VMS pore water samples, data and analyses offer unparalleled insights into potential contamination and processes in the subsurface above the aquifer, before they occur. VMS data analyses services facilitate early detection, effective mitigation strategies, and timely interventions in a range of applications and groundwater protection activities.